Honlik: Stainless Sensor Craftsmen

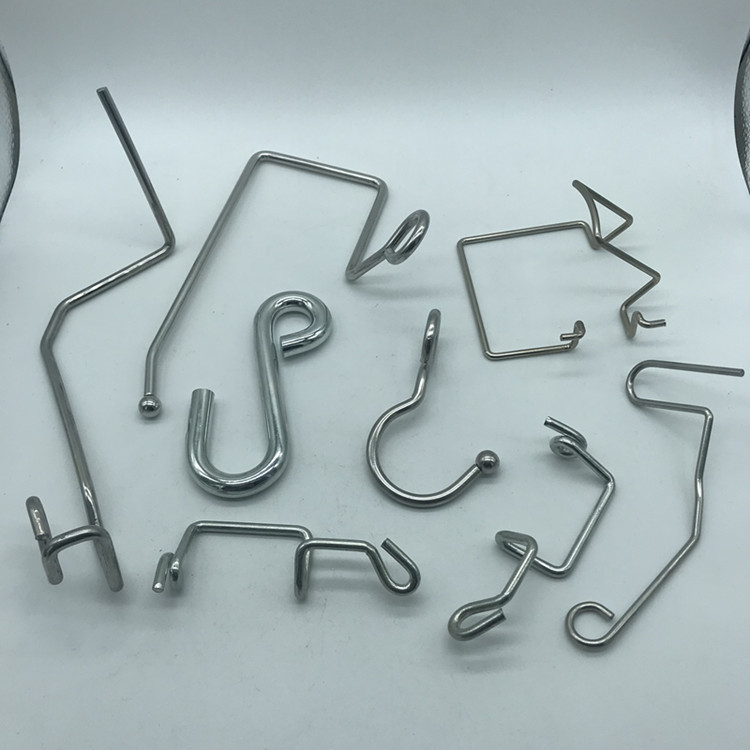

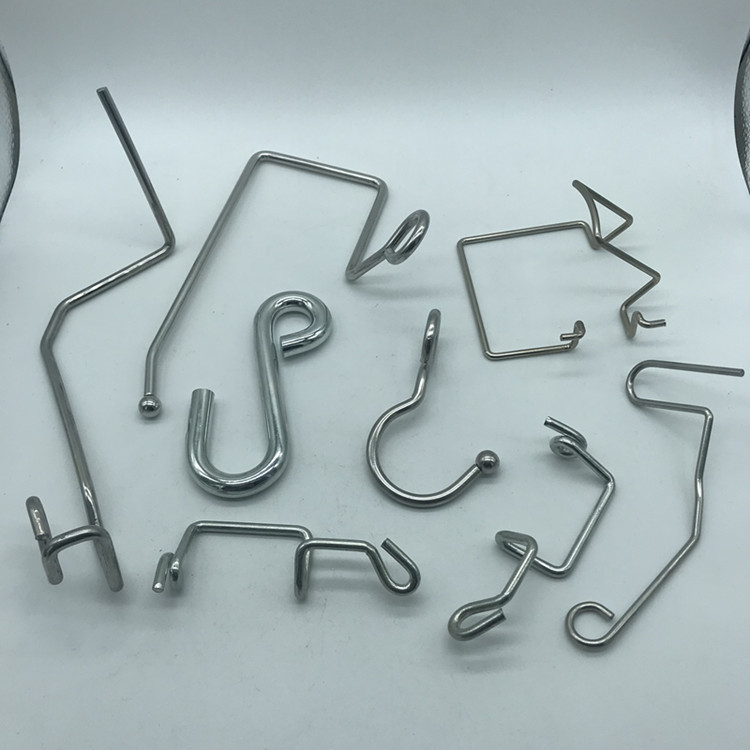

In the realm of precision engineering, Honlik has emerged as a leading custom stainless steel sensor parts manufacturer based in China, renowned for its expertise in crafting corrosion-resistant, high-performance components for industrial automation, automotive systems, and IoT devices. Specializing in SUS304 stainless steel sensor components, induction sensor bracket clips, and bespoke sensor mounts, Honlik caters to OEMs, engineers, and distributors seeking durable, cost-effective solutions for demanding applications.

As a trusted wholesale sensor components supplier, Honlik understands that reliability and adaptability are paramount. Whether it’s a compact SUS304 housing for a proximity sensor or a ruggedized bracket clip for an induction sensor in harsh environments, the brand’s engineering team collaborates closely with clients to design parts that meet exacting specifications. From material selection (e.g., 304 vs. 316L stainless steel) to surface finishes (e.g., polished, passivated, or sandblasted), Honlik ensures flexibility without compromising structural integrity.

One of Honlik’s core strengths lies in its SUS304 stainless steel sensor components. Engineered for exceptional corrosion resistance and mechanical strength, these parts excel in applications like food processing machinery, medical devices, and marine sensors. Their non-magnetic properties and thermal stability make them ideal for temperature-sensitive environments, while their precision machining tolerances (down to ±0.01mm) guarantee seamless integration with sensor electronics.

For industries requiring robust mounting solutions, Honlik’s induction sensor bracket clips are a game-changer. Designed to withstand vibration, shock, and extreme temperatures, these clips secure sensors in place while allowing quick adjustments for calibration. Customizable features include clip thickness, spring tension, and mounting hole patterns, ensuring compatibility with a wide range of sensor models and machinery designs.

China’s manufacturing ecosystem fuels Honlik’s competitive edge. By leveraging CNC milling, laser cutting, and robotic welding, the brand achieves tight dimensional accuracy and consistent quality across batches. Its vertically integrated supply chain—from stainless steel coil sourcing to final packaging—enables cost-effective pricing, making Honlik a go-to choice for bulk orders and just-in-time deliveries.

For businesses seeking custom stainless steel sensor parts, Honlik offers a seamless workflow. Clients can submit 3D models, tolerance requirements, or environmental constraints, and the brand’s experts will recommend the optimal material grade, finishing process, and assembly method. Specialty services include prototyping, heat treatment for enhanced hardness, and EMI shielding for electromagnetic interference protection.

Honlik’s commitment to innovation extends beyond hardware. The brand invests in smart manufacturing technologies, such as AI-driven quality inspection and real-time production tracking, to ensure on-time delivery and zero defects. Its eco-friendly initiatives, including recycling metal scrap and using water-based cleaning agents, align with modern sustainability goals.

For OEMs, engineers, and distributors, partnering with Honlik means accessing a one-stop shop for stainless steel sensor solutions. The brand’s agility in handling small prototyping runs and large-scale industrial projects, coupled with its global compliance certifications (e.g., RoHS, REACH), has earned it a loyal clientele spanning 30+ countries.

In conclusion, Honlik is more than a manufacturer—it’s a strategic partner in sensor excellence. By blending Chinese engineering precision with global quality standards, the brand continues to redefine stainless steel sensor component technology. Whether you need SUS304 parts for cutting-edge automation or custom induction sensor clips for rugged environments, Honlik delivers components that sense smarter, last longer, and cost less.