What is sheet metal and what are its functions?

Sheet metal, a processing technique, has yet to have a complete definition. According to a definition found in a foreign professional journal, it can be defined as follows: Sheet metal is a comprehensive cold processing technique for metal sheets (usually below 6mm), including shearing, punching/cutting/compound cutting, bending, riveting, assembling, forming (such as automobile body), etc. Its significant characteristic is that the thickness of the same part is consistent.

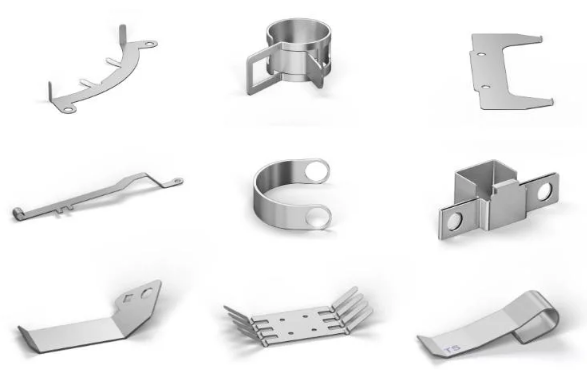

Sheet metal features lightweight, high strength, conductivity (suitable for electromagnetic shielding), low cost, and good mass production performance. It has been widely used in electronics, communication, automotive, medical equipment, and other fields. For example, in computer cases, mobile phones, MP3 players, sheet metal is an indispensable component.

As the application of sheet metal becomes more widespread, the design of sheet metal parts has become an important part of the product development process. Mechanical engineers must master the design techniques of sheet metal parts proficiently, ensuring that the designed sheet metal meets the requirements of product functionality and appearance while making the stamping die manufacturing simple and cost-effective.

Based on the above reasons, it is necessary to systematically organize information on the structural design of sheet metal parts, which is believed to have some effect on users of the internet.

Thin plates refer to steel plates with much smaller thicknesses compared to their lengths and widths. They have poor lateral bending resistance and are not suitable for occasions subject to lateral bending loads. Thin plates are made of metal, but due to their special geometric shapes and small thicknesses, the processing technology of thin plate components has its peculiarities. There are three types of processing technologies related to thin plate components:

(1) Cutting: It includes shearing and punching.

(2) Forming: It includes bending, folding, edge rolling, and deep drawing.

(3) Connection: It includes welding, bonding, etc. The structural design of thin plate components should mainly consider the requirements and characteristics of the processing technology. In addition, attention should be paid to the batch size of the components.

Thin plate components are widely adopted because thin plates have the following advantages:

(1) They are easy to deform, allowing the manufacture of various forms of components using simple processing techniques.

(2) Thin plate components are lightweight.

(3) They require minimal processing, as the surface quality of thin plates is high, and the thickness direction size tolerance is small, with no need for surface machining.

(4) They are easy to cut and weld, allowing the manufacture of large and complex components.

(5) They have standardized shapes, making them suitable for automatic processing.